ENGINEERS EXPERIENCE

TLG engineers have extensive analysis and test experience with over 100 different aircraft models from more than 40 different manufacturers. Our experience includes aerodynamic design and analysis, static and dynamic loads and response analyses, flutter analyses, stress and design, wind tunnel, ground and flight testing. Our engineers have performed engineering design, development, validation and certification engineering for over 100 Type Certificate (TC), Supplemental Type Certificate (STC), product development and special mission/purpose projects.

LOADS AND FLUTTER

- FAA Loads and Flutter DER (14 CFR Part 23 and 25)

- Static and Dynamic Loads for Strength, Fatigue and Damage Tolerance

- Flutter Analysis and Design for Aeroservoelastic Stability Margin

- Flight and Ground Testing for Loads and Flutter Certification

- Feasibility Studies and Product Development

- Engineering Project Management

- Simulation of Failure Modes including FCS Failure and Blade-out Conditions

- Fuselage Decompression Loads

- Full Aeroservoelastic Calculation Capabilities

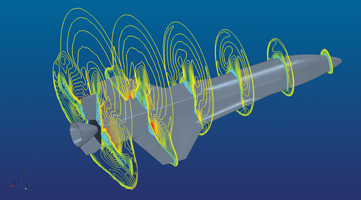

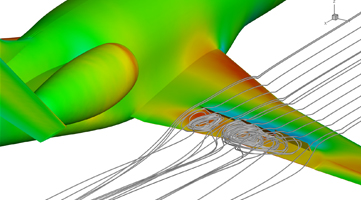

Aerodynamic Design and CFD Analysis

- Applied Aerodynamics Expertise

- Full CFD Capability, Panel Methods to Navier-Stokes

- Concept Exploration, Aircraft Sizing and Preliminary Design

- Internal and External Flows, Subsonic, Transonic, Supersonic and Hypersonic including Chemical Reacting Nonequilibrium Flows

- Design of Airfoils, Wings, Control Surfaces, High-lift Devices, Fairings, Antennae, Nacelles, Struts, Inlets, Ducts, etc.

- Power Plant Integration

- Thermodynamic and Heat Rejection Analysis

- Scalable Analysis using On-site and Cloud Based Computing Clusters

- Wind Tunnel Testing, Low Speed and Transonic, Quick Reaction and Production

FAA Certification

- Certification Plans

- Agency Certification Coordination (FAA, EASA, Others)

- STC and TC Certification Documentation

- Test Witnessing

- FAA DER Approvals Performance, Stability and Control, and Handling Qualities

- FAA Flight Analyst DER (14 CFR Part 23)

- Performance Prediction, Measurement and Validation

- Mission Analysis and Optimization

- AFM-based Performance Modeling

Classical and Non-linear Stability and Control Analysis

- Flight Dynamics Simulation

- Aeroelastic and Closed Loop Handling Qualities Analysis

- Flight and Ground Test Planning, Support and Analysis

Stress and Design

- FAA Structures DER (14 CFR Part 23 and 25)

- Metallic and Composite Analysis and Design

- Static, Fatigue and Damage Tolerance Analysis

- Bird Strike and Rotor Burst Impact Simulation

- Industry Standard Analysis Tools

- Finite Element Analysis Experience

- Industry Standard Design using CATIA V5

- Continued Airworthiness Documentation

- Support In-service Major Repairs and Alterations

- Ground Test Planning, Support and Analysis

o PATRAN/NASTRAN/APEX

Includes:

o Linear Static

o Modal and Frequency Response

o Buckling

o Implicit and Explicit Nonlinear

o Optimization

o Thermal

o Validated by Test or Classical Methods

o Trade Studies and Concept Development

o 3D Model Based or 2D Drawings